I want to live in a world where millions of people work and live in space

A world where a space company can be launched from a dorm room, and where every small business can get value from data collected in orbit.

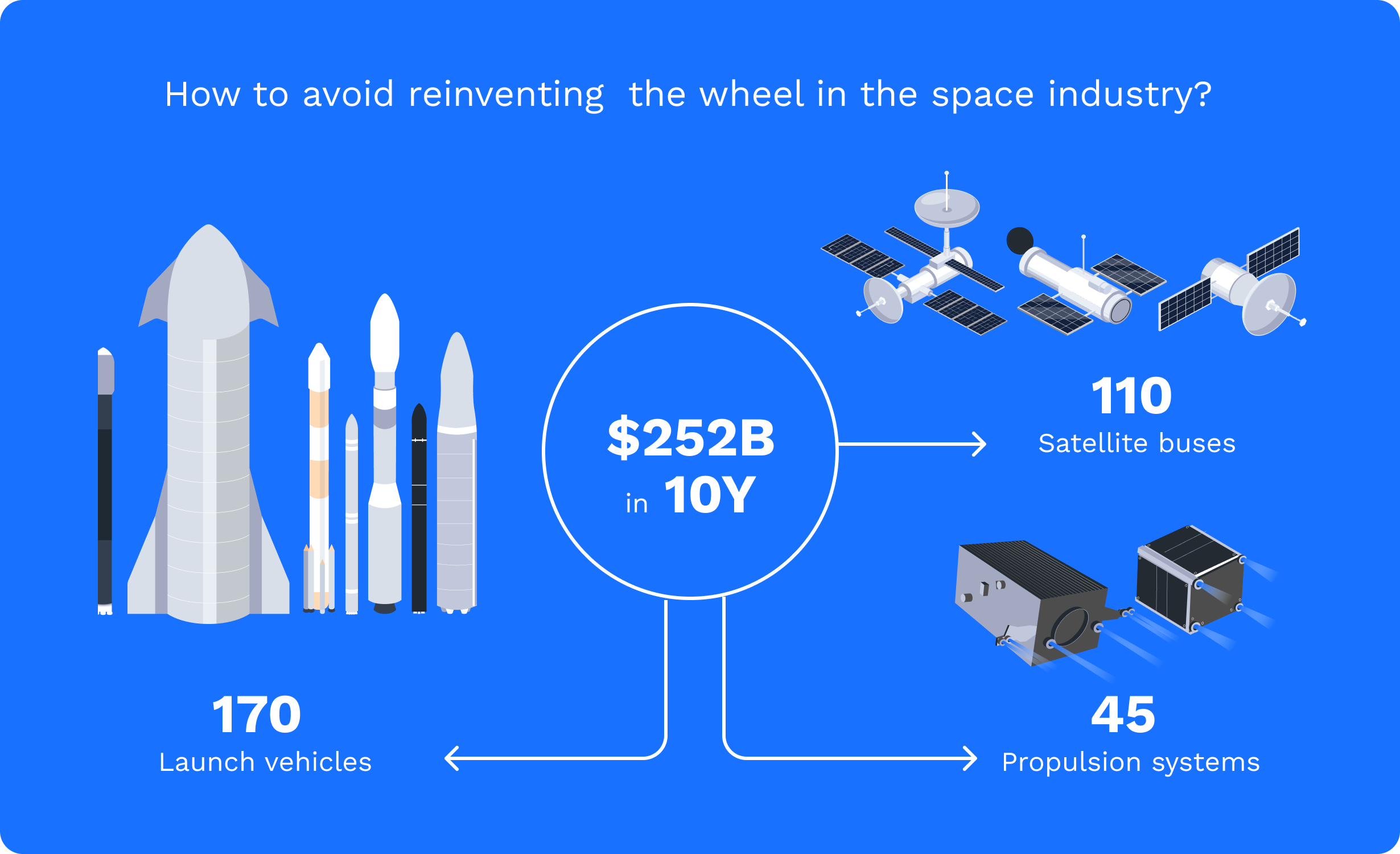

Over the last ten years, humanity has invested over $252.9 billion in attempting to make space accessible and affordable. Some breakthrough achievements have been made, including the advent of reusable rockets and the proliferation of modular satellites (aka CubeSats).

The same cannot be said for breakthrough businesses. The industry is still struggling to turn capital expenditure into sustainable operating margin — this is due, in part, to the massive amount of rework that still exists with each and every new mission. In simple terms, it would be like reinventing the PC, the mouse, and even the surge protector every time a new company is formed.

Space is hard, but the business of space doesn’t have to be

Challenge

There are numerous factors outside of anyone’s control that impact the health and capability of systems in space. Space itself is a harsh environment and systems therein must withstand radiation (sustained and single upset events), orbital speeds over 4.2 miles/ second, errant space debris, brutal launch conditions that include extreme vibration and heat applied to sensitive electronics, and stringent mass budgets and power constraints to name just a few.

Bringing valuable data to customers from even a simple sensor in space is one of the hardest engineering and management challenges humanity has ever faced.

Launching an MVP to space takes a village: systems, mechanical, software, and communications work together with mission designers and orbital mechanics to scope the project, and then with a small army of managers to weave together the supply chain of dozens of disparate vendors spread across the world.

And then… a single requirement change. Again, in simple terms, a single requirement change is equivalent to tipping the first domino in a long chain of dominos. All of these systems are so interconnected to one another that a single change compounds, resulting in months or even years of rework, let alone any impact to the launch — this is booked far in advance, and in most cases, will happen whether or not your project is ready, and without concern for any rework you may have.

Solution

Over the last five years, we have been meticulously collecting, analyzing, and normalizing everything we learned from working on more than 100 successful space missions.

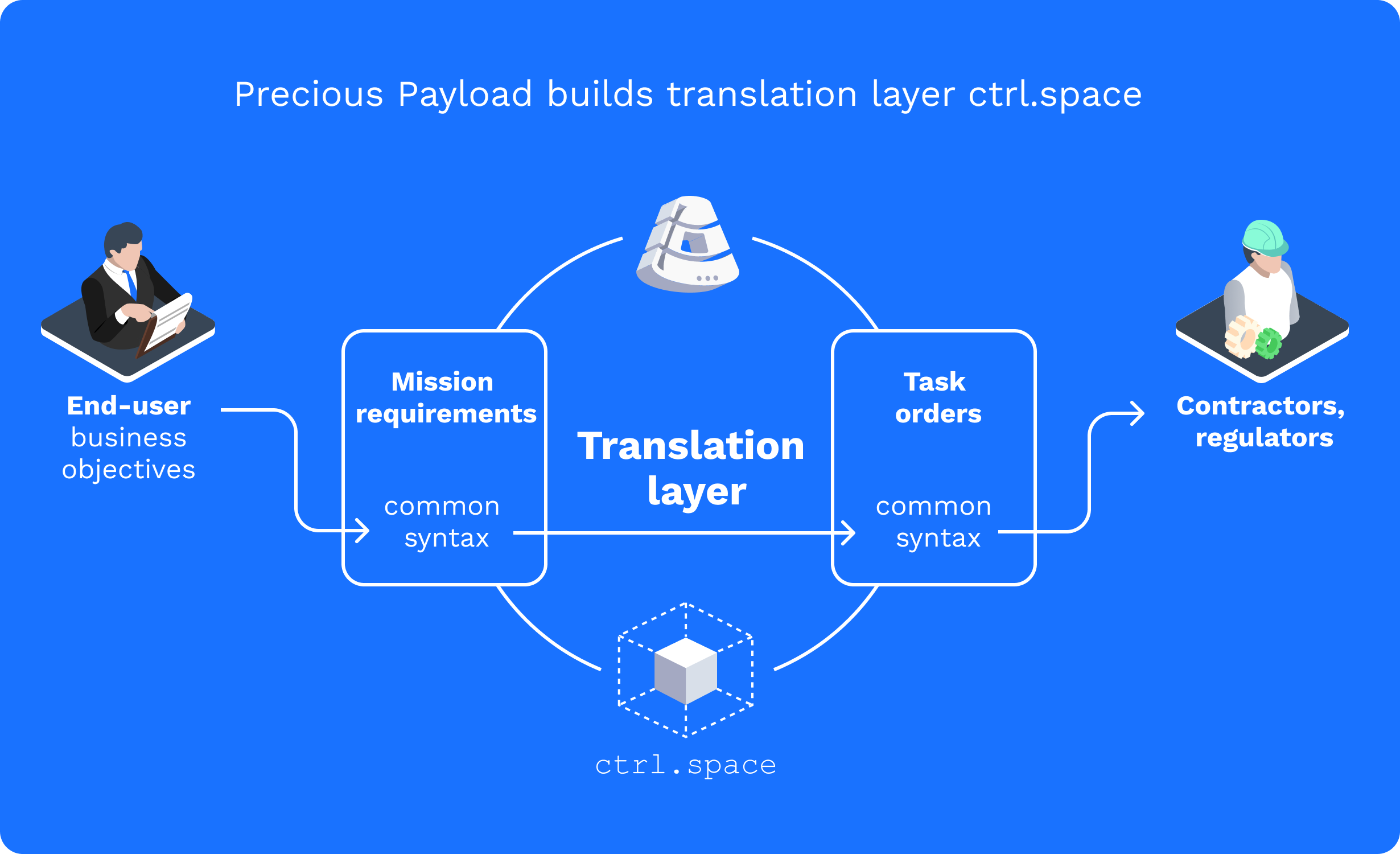

Our key insight is that the end-user business objectives of a space mission can be decomposed into mission requirements using a common syntax. These requirements are easily translated into task orders for space industry contractors and regulators.

We developed this translation layer for seamless movement of data and actions across teams. This common syntax captured in our translation layer will increase the ultimate volume and velocity of satellite missions across the entire space industry.

It takes 4-years and $8 million today, on average, to launch a space mission, setting aside proof of concept or test missions with limited usefulness. We believe that we can reduce that time to 6-months, and we can do it for ¼ the cost.

By abstracting away from the requirements and delivering a normalized task list for mission operators, we are liberating essential engineering time to work on what really matters: perfecting the precious payload — aka, the key competitive advantage — and optimizing the business model to deliver maximum value.

Launch control

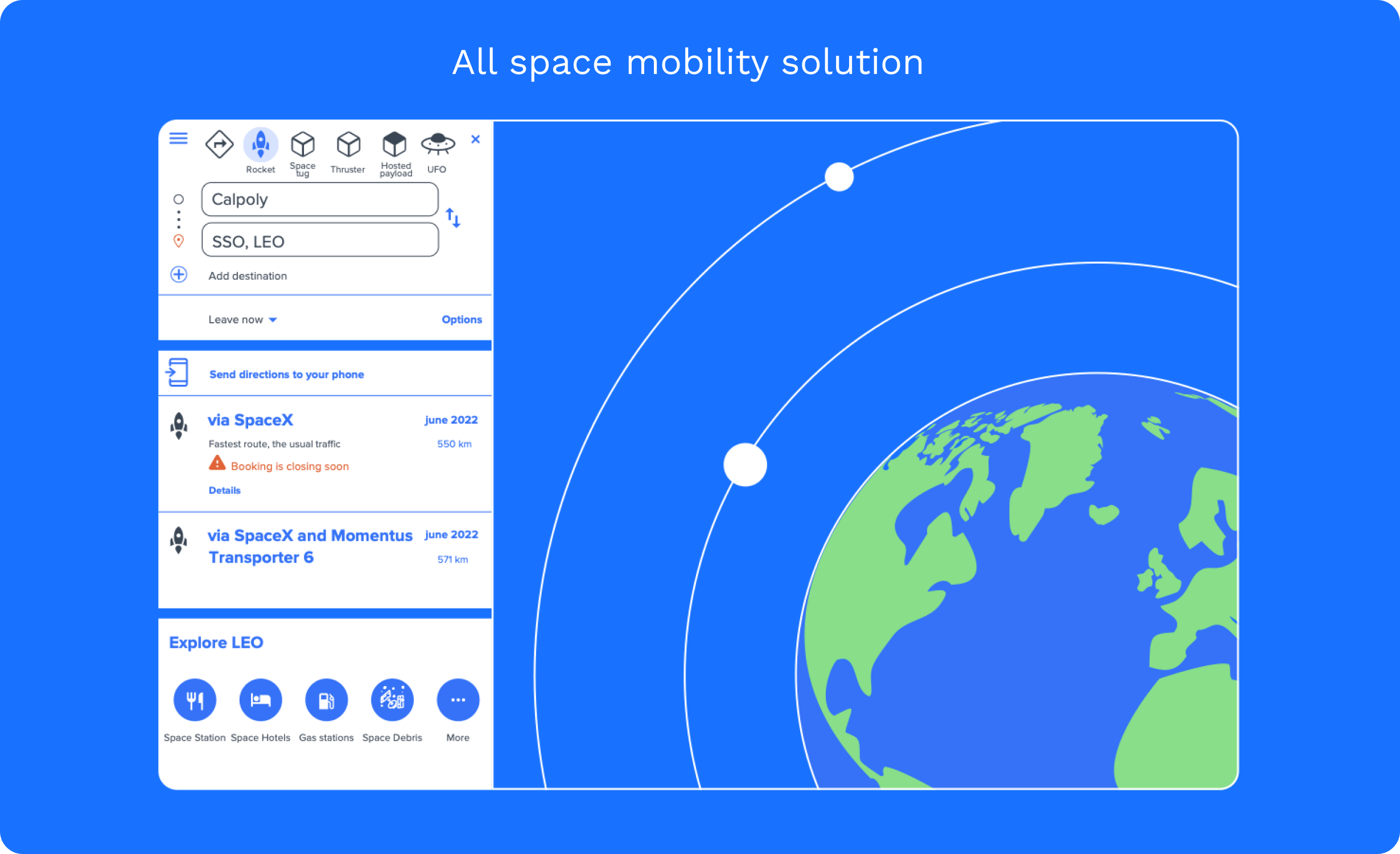

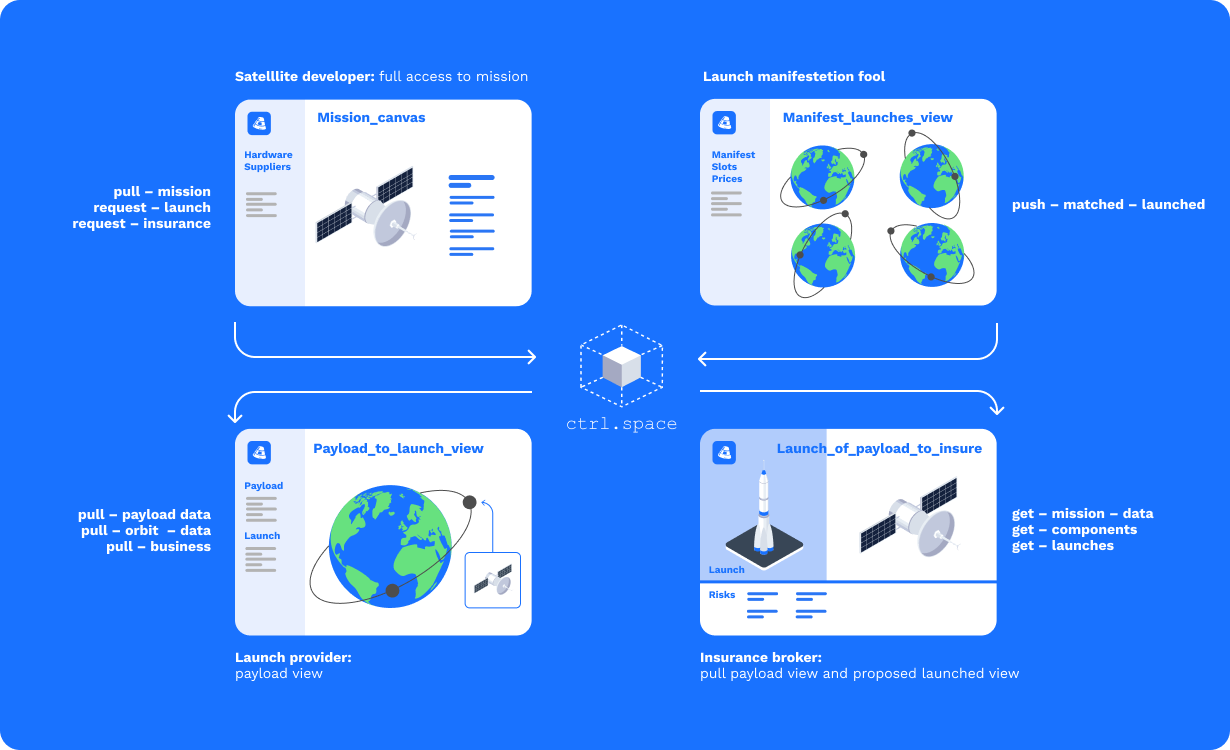

Our first product Launch.ctrl is a gateway to all space mobility solutions available on the market. Engineers plan their optimal route to a destination in orbit using verified and actionable data specific to their mission design.

The proliferation of new launch vehicles, space tugs, and thrusters have made in-space logistics a multi-modal problem to solve. We automated the complexity away from this process.

Learn more

Learn moreProduct roadmap

Access to space is core to every company in this sector. Securing a launch is a gating function for increasing tech readiness level, funding, and acquiring first paying customers. It also has a cascading effect on decision-making across different areas of the business, from product to hiring/retention, and mission design.

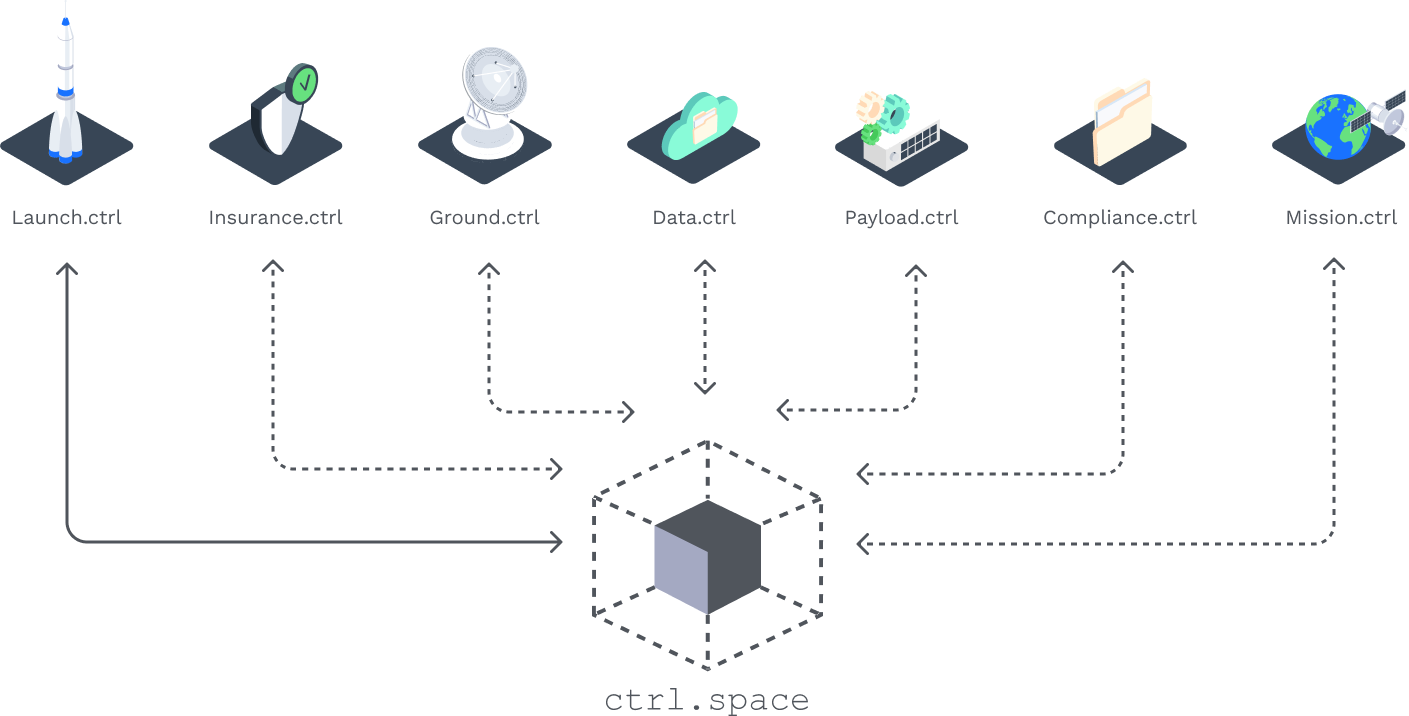

A decision on the launch should be taken in consideration with all other aspects of mission planning. Integration with key space infrastructure companies across 6 main building blocks enables end-to-end mission execution for our customers.

Product

We're always working to improve our products, and we want to be sure that you're up-to-date on all the latest features and updates

View changelogGround control

Most engineers adopt a waterfall approach: draft a mission design, secure a launch, find a matching ground station provider. In reality, ⅔ of teams revisit their launch plans or communication subsystem entirely after talking to ground segment providers.

Using Ground.ctrl block enables running space-to-ground communication concept analysis concurrently with launch options selection. You build a mission profile, obtain launch options, match them with active ground stations, and iterate on mission design. As a result, our customers reduce their time-to-orbit for up to 6 months, saving hundreds of thousands of dollars in rework.

Insurance control

Downside protection is one of the key enablers of a sustainable commercialisation of space. However, space insurance companies struggle to adopt their business model to work with New Space companies.

As a result, the very insignificant amount of satellites being launched have procured any insurance at all. Decomposing the underwriting procedures into a fixed dataset on the customer’s company and mission profile reduces complexity of most common insurance products: TPL, LVFO, and pre-launch operations.

Payload control

Managing satellite subsystems and component suppliers account for up to 60% of the engineering time during mission design and production phases. Identifying, contracting, and negotiating requirements needs dozens of offline and online meetings, NDAs and countless email chains.

Having a common environment to get existing and prospective suppliers up to speed on the latest mission design decisions automates the discovery and reduces the amount of sync calls to 1h per week.

Existing space industry marketplaces and hardware vendors feed their product data to Payload.ctrl through the API, making it available to engineers while they are iterating on the mission design.

Compliance control

Despite the fact that obtaining appropriate radio frequency and remote sensing licenses are mandatory for most of the missions, most of these filings are made last-minute and outsourced to the extremely expensive consultants. Missing important deadlines or failure to provide the necessary paperwork can undo years of hard work.

Knowing the realistic licensing scope, timelines, and automation of the paperwork preparation reduces the unnecessary risk of non-compliance for a mission.

Mission control

Space is becoming a congested environment, and the operations phase of a space mission requires constant monitoring of the traffic. In the near future, almost every satellite will provide tasking functionality for its customers, enabling them to precisely point cameras or antennas at the points of interest.

Developing such capabilities requires a deep software integration on a subsystems level of a spacecraft. Building a spacecraft using Precious Payload software creates a digital twin of an asset in orbit, providing a robust environment for testing, troubleshooting, and tasking the sensors onboard.

Data control

Value extraction from the space-derived data is the reason why we launch satellites. Downloading, storage, processing and distribution of sensor data is often overlooked or kept in the backlog for too long.

Leveraging existing cloud-based solutions such as AWS or Azure instead of reinventing the wheel significantly reduces the time-to-market for our customers.